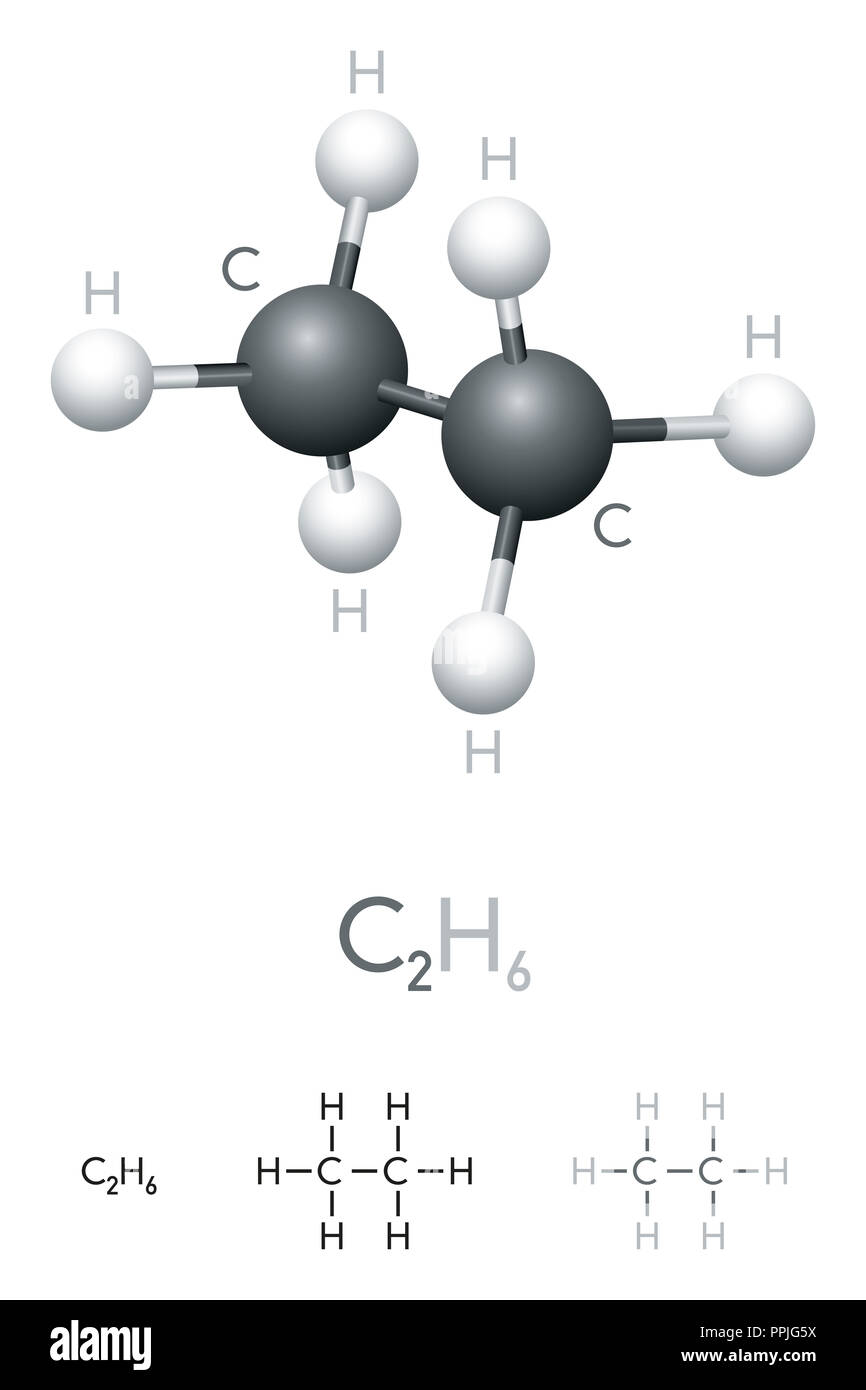

Is Ethane merely a simple hydrocarbon, or does it hold the key to unlocking significant advancements across diverse industries? Ethane, a seemingly unassuming molecule composed of two carbon atoms and six hydrogen atoms, is proving to be a critical component in the modern industrial landscape, offering innovative solutions in areas ranging from network architecture to petrochemical production, all while presenting both opportunities and challenges to consider.

The pervasive influence of ethane extends far beyond its elemental composition, impacting fields from computer science to petrochemical processing. Its versatility and unique properties make it an indispensable raw material, fueling progress and innovation in myriad sectors. For instance, in the realm of network architecture, the Ethane system has revolutionized enterprise networks, and in the petrochemical industry, ethane is vital for the production of ethylene, a key building block for plastics and other essential products.

| Ethane: Key Properties and Applications | |

|---|---|

| Chemical Formula: | C₂H₆ |

| Molecular Weight: | 30.07 g/mol |

| Boiling Point: | -88.5 °C (-127.3 °F) |

| Melting Point: | -182.8 °C (-297 °F) |

| Main Uses: |

|

| Industrial Importance: | A crucial component in the petrochemical industry for the production of ethylene, a vital building block for plastics, synthetic rubber, and other valuable products. Also used in various industrial processes and as a fuel. |

For additional reference, you can check the properties of ethane and its applications at the following link: Wikipedia: Ethane.

The Ethane network architecture, implemented in both software and hardware, represents a bold step forward in enterprise network management. Designed to simplify and secure network operations, Ethane utilizes a centralized controller and flow-based Ethernet switches to enforce a single, network-wide policy. This innovative approach allows managers to define fine-grain policies and ensures their direct enforcement, ultimately leading to improved network performance and enhanced security. The core principle of Ethane rests on coupling simple flow-based Ethernet switches with a centralized controller, which adeptly manages the admission and routing of network traffic. This method allows network administrators to define a singular, global policy and implement it directly, effectively simplifying network management and bolstering security.

In the petrochemical sector, the separation of ethane and ethylene is a critical and energy-intensive process. This process becomes essential to efficiently purify ethylene, which serves as a vital building block for numerous downstream products. Research in this area focuses on developing advanced materials, such as metal-organic frameworks (MOFs), that can selectively separate these two hydrocarbons. For instance, the microporous metal-organic framework, iron(III) peroxide 2,5-dioxido-1,4-benzenedicarboxylate [Fe2(O2)(dobdc)], has shown promise in this area, offering a fresh avenue for achieving highly selective separations. These advancements are crucial for improving the efficiency and sustainability of petrochemical processes.

The Falcon Ethane Pipeline System, spanning 97 miles, stands as a significant infrastructure project designed to transport ethane. This pipeline connects major ethane source points in Pennsylvania and Ohio, facilitating the reliable delivery of this crucial hydrocarbon. Constructed by Shell Pipeline, the Falcon Ethane Pipeline is vital to the supply chain, moving ethane from production sites to processing facilities and end-users. The existence of robust and dependable pipeline infrastructure ensures the efficient transport of ethane, supporting the growth of the petrochemical industry in the region.

The strategic importance of ethane has driven the development of robust infrastructure, such as the Bayou Ethane Pipeline, operated by Boardwalk Pipelines. This pipeline links ethane producers and consumers, particularly in areas like Mont Belvieu, Texas, and the Mississippi River Corridor. Serving as a common carrier, the Bayou Ethane Pipeline plays a pivotal role in ensuring a steady supply of ethane, supporting the operations of downstream processing facilities and contributing to the overall efficiency of the industry. The network of pipelines and infrastructure highlights the crucial role ethane plays in the energy sector and the broader economy.

However, the use of ethane also presents certain hazards. Ethane is listed on the Hazardous Substance List due to its classification by various regulatory bodies such as ACGIH, DOT, DEP, and NFPA. This categorization highlights the importance of implementing safety measures to mitigate potential risks. These classifications emphasize the need for responsible handling, storage, and transportation of ethane to protect the health of workers and the environment.

The drive for efficient ethane separation is evident in the ongoing research. The focus is on improving the techniques and materials used to isolate ethane from other hydrocarbons, which is crucial for a variety of industrial applications. The development of robust and selective separation methods is essential for optimizing processes and minimizing energy consumption in the chemical industry.