Is a 97-mile pipeline system the key to unlocking a new era of energy infrastructure? The Falcon Ethane Pipeline System, a project spearheaded by Shell Pipeline, promises to revolutionize the transportation of ethane, connecting vital resource points across Pennsylvania, West Virginia, and Ohio.

The project, designed to connect three major ethane source points, represents a significant investment in the region's energy future. The primary goal is to create a reliable and efficient infrastructure for transporting this crucial hydrocarbon. The Falcon Ethane Pipeline System is poised to become a cornerstone of the regional energy landscape, facilitating the movement of ethane from its sources to processing and distribution centers, ensuring a consistent supply for various industrial applications.

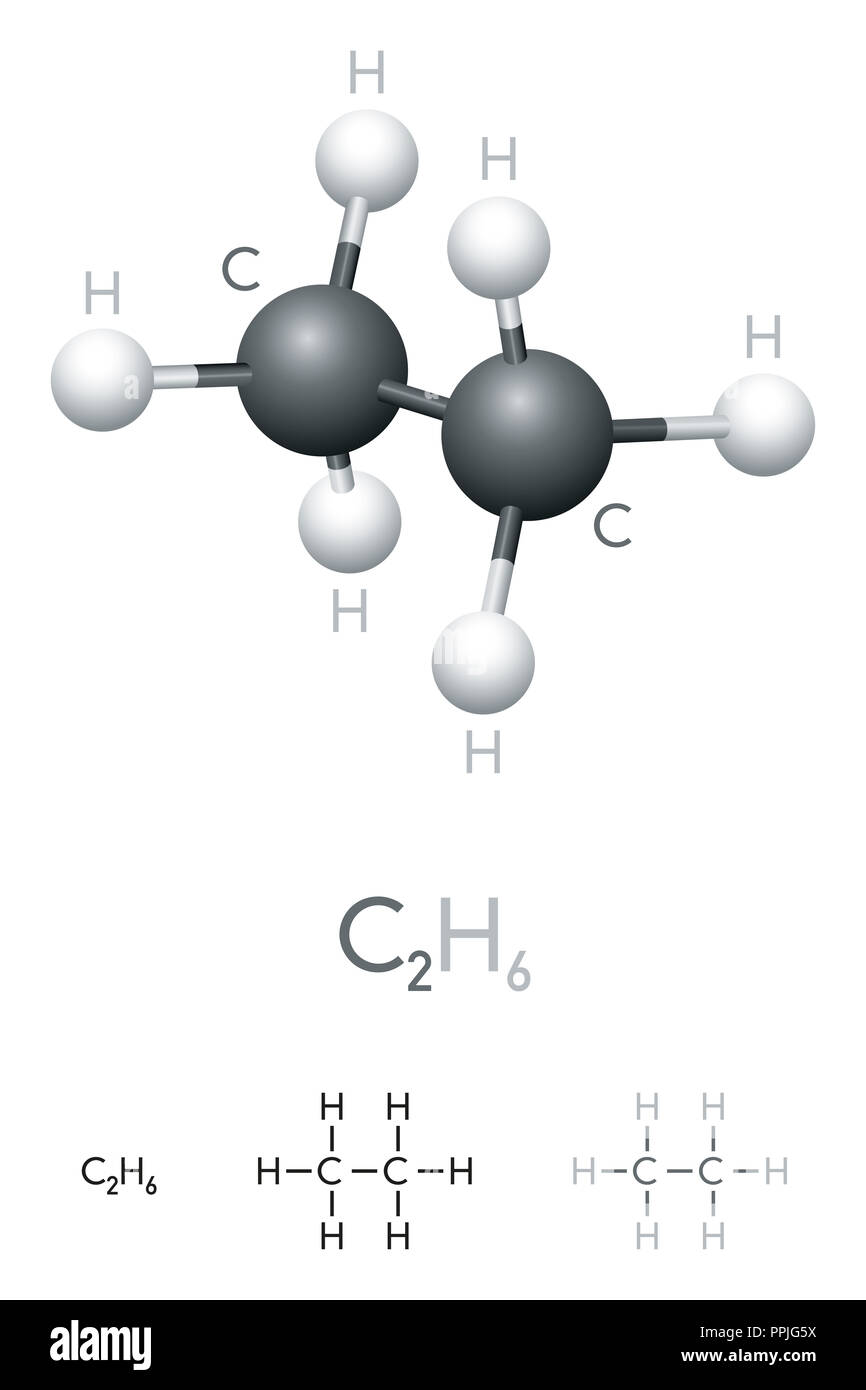

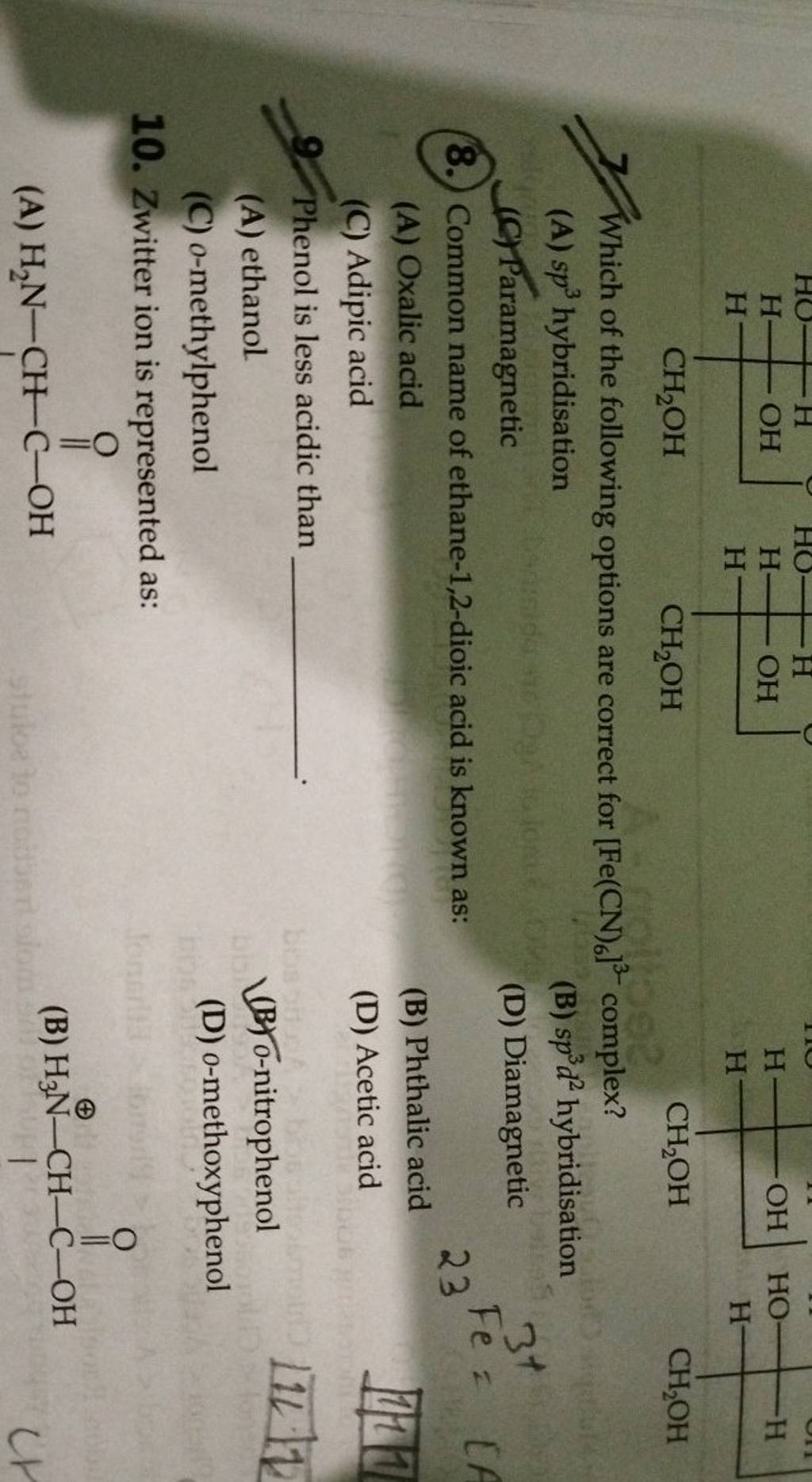

Let's delve into the technical aspects of this essential hydrocarbon. Ethane, a simple alkane composed of two carbon atoms, is the second-largest component of natural gas and plays a pivotal role in the petrochemical industry. Beyond its immediate applications as a fuel source, ethane serves as a critical feedstock for the production of ethylene, a fundamental building block for plastics, solvents, and a vast array of other products that underpin modern life. The chemical formula of ethane is CH3CH3, a testament to its straightforward molecular structure.

The project's focus on ethane stems from its significance in both present and emerging energy strategies. Ethane serves as a refrigerant and plant metabolite and as a core component in the production of ethylene. In fact, the separation of ethane from ethylene is an important and challenging process in the chemical industry, demanding efficiency and innovative technology. As the demand for petrochemical products continues to rise globally, the demand for ethane will grow, as well, making the Falcon Ethane Pipeline System an important piece of infrastructure.

In today's ever-evolving world, several organizations and regulatory bodies recognize the importance of ethane. Ethane is on the Hazardous Substance List, cited by various agencies and is on the Special Health Hazard Substance List. These designations underscore the need for vigilance and responsible handling throughout the pipeline's operations. It calls for best practices in management to keep safety paramount.

Beyond its role as a raw material, ethane is also used in the energy sector. The gas also is used in various projects that focus on reducing harmful emissions. For example, researchers are studying ways to convert CO2 and ethane into useful, desired products. This research may provide a potential pathway to decrease reliance on greenhouse gasses.

Technological advancement is crucial for this project. In one example, researchers have developed a metal-organic framework, iron(III) peroxide 2,5-dioxido-1,4-benzenedicarboxylate [Fe2(O2)(dobdc) (dobdc) to assist with the separation of ethane from ethylene. This highlights the importance of ongoing innovation in the field.

In the world of technology, innovation has allowed companies to create centralized control systems that manage the admittance and routing of flows in Ethernet switches. An example of this is Ethane, a network architecture for enterprises. By allowing managers to define a single network-wide policy and enforce it directly, these networks have created a way to streamline communications.

The Falcon Ethane Pipeline System will be an integral part of the region's energy landscape. With its ability to efficiently transport a key raw material, the pipeline will serve as a bridge between sources, processors, and end users. As the energy needs of the region evolve, this project will continue to play a significant role in securing a robust and sustainable energy future.

The impact of the Falcon Ethane Pipeline System extends beyond the transportation of a single substance. It represents a broader shift towards optimizing energy infrastructure, reducing transportation costs, and improving the overall efficiency of the energy supply chain. It also reflects the ongoing commitment to responsibly managing essential resources, while also taking steps to limit environmental risks.

The Falcon Ethane Pipeline System, once completed, will connect the source points in Pennsylvania and Ohio. These areas have become hubs of energy production. The system's strategic placement will provide access to critical ethane resources, making it a significant factor in driving economic growth and energy independence within the region. It is also an excellent example of infrastructure developments, as it helps reduce bottlenecks and improve efficiency.

The development of the Falcon Ethane Pipeline System also has a wide range of industrial applications. Ethane is the primary building block for creating ethylene, which is a key raw material for the production of plastics, synthetic fibers, and solvents. The pipeline system's presence will not only ensure a steady supply of raw materials, but it will also support the growth of manufacturing sectors that rely on these products.

The system has taken on several hurdles to ensure its success. The pipeline will adhere to the highest safety and environmental standards, from its construction to its operations. The adherence to safety and environmental regulations will be necessary for preserving the surrounding environment.

As the Falcon Ethane Pipeline System takes shape, it embodies the dynamic interplay of energy, industry, and technological progress. The ongoing commitment to innovation, responsible stewardship, and economic progress underscores the potential of projects like this.